Separ Fuel Filter / Water Separators

Separ Fuel Filter /

Water Separator

Specifications

Separ Fuel Water Separators Specifications

Water Separation and Particulate Filtration

The SEPAR SWK-2000 Series is a line of fuel water separators and fuel filter that is designed to accommodate newer and more demanding diesel engines. They are manufactured from high quality, non-corroding aluminum alloy castings, heavy polycarbonate or metal bowls and stainless steel hardware. Fuel systems are protected and engine failure is avoided by the filters’ ability to separate harmful particulate and water from diesel fuel.

The Separ Advantage…

- Advanced filtration for diesel engine reliability

> 99.9% Water separation (certified TUV report using SAE J1839) and removes sludge build-up - Longer element life

> Filter separates most debris and large particles before reaching the element - Less element replacements

> User can backflush filter up to 5 times before replacing element - Low restriction reduces wear on fuel pumps and ensures full RPMs

Fuel water separators feature five stages of filtration and are available with flow rates from 79 to 2,060 GPH for appropriate integration into any size fuel system. The benefits include a small physical size, high flow rate, low restriction, multiple inlet/outlet configurations and long-life filter elements. A 30 micron filter element is installed (standard) and replacement filter elements are available in 10 and 30 micron element, and a 60 micron stainless steel element. All filter elements are “blackflushable” (cleanable) that reduces down-time and costly element changes.

Duplex systems contain two filters. When the primary filter is in need of maintenance, the fuel system can continue to operate by use of the secondary filter. This reduces down time and increases dependability.

Water and solid contaminants displace the fuel’s lubricative coating on the high precision injection components. The loss of this protection results in wear, erosion, surface pitting and eventual pressure loss.

Many existing fuel filters aren’t designed to remove significant amounts of water. They are designed to do their job in a single step. The Separ 2000 offers a compact design, high efficiency, low flow restriction, a long life filter element, easy installation, and simple maintenance.

Main Features:

- Available with various flow rates from 1 to 34 GPM (68 GPM in Duplex) (129 LPM (260 LPM in Duplex)). Thereby offering fuel filters for an engine performance range of 5 to 10,000 kw.

- Compact size, various ports, simple installation.

- Manufactured from high quality non-corroding aluminum alloy casting, heavy polycarbonate or metal bowls and stainless steel hardware.

- High separation efficiency of water which is contained in the fuel.

- Low Restriction

- Extended service time of the filter elements.

- Protects the injection pump and injection nozzles.

- Simple installation

- Long life filter elements (Stainless Steel washable elements available)

- Backflushable

- Easy maintenance.

Applications:

- Automotive industry – trucks, buses, mobile cranes, municipality vehicles, etc.

- Construction equipment, compressor sets, agricultural equipment, fork lifts, etc.

- Stationary engines – generators, welding and pumping installations, etc.

- Mining applications

- Marine Propulsion (including switchable filters. A water level indication can be supplied optionally)

- U.S. Navy and U.S. Coast Guard

- Custom versions available

Class Certificates

- American Bureau of Shipping Certificate

- RINA

- Bureau Veritas Type Approval Certificate

- Lloyd Type Approval Certificate

- Rheinisch-Westfälischer TÜV

- Kraftfahrt-Bundesamt Flensburg

- German Technical Department of Arm Ship and Marine Weapons

- Germanischer Lloyd Type Approval Certificate

Features of the SEPAR 2000:

- Small physical size in comparison to flow rate.

- High performance.

- Low restriction (delta P)

- Long-life filter element.

- Easy installation.

- Simple in operation.

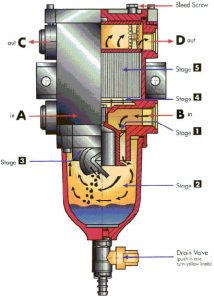

How the SEPAR 2000 Operates:

SEPAR Filter

Cut-Away

Fuel is sucked into the filter by the action of the lift pump via either port A or B. Plug off the port that is not being used with the plug provided. The filter is designed for the suction side of the engine.

STAGE 1

The diesel fuel enters the filter through either inlet port A or B. The second inlet (not used) should be sealed with the plug provided

From the inlet port, fuel flows through the interior vane system which imparts a circular motion to the fuel

STAGE 2

Still in the circular motion, fuel reaches the bowl section, where water droplets and heavier particles are forced to the wall of the bottle and eventually settle at the bottom.

STAGE 3

In this stage, the fuel passes the vane system positioned on the “outside” of the central housing. Due to the differing length of the vanes and the two-fold rapid change of flow direction, smaller water droplets and particles will settle on the vanes. When the accumulation is heavy enough, it will fall to the bottom of the bowl. At this point, a major portion of the contaminants in the fuel have been separated.

STAGE 4

Just below the filter element, the flow area is increased significantly thus reducing fuel flow rate. This calming effect allows even smaller water droplets and particulate to fall out and settle on the inner surfaces of the housing forming larger droplets which eventually fall into the bottom of the bowl by gravity.

Due to the previously described pre-separation process, the major portion of water and particulate present in the fuel will be in the bowl or on the inner surfaces of the filter. Thus, greatly extending the filter element life.

STAGE 5

The final filtration of the remaining water and particulate still contained in the fuel will be removed by a replaceable element. These filter elements are produced from a special filter media and are available in different pore sizes. The clean fuel leaves the filter through outlet port C or D.

The second outlet port (that is not used) should be sealed with the plug provided. If a gauge kit is used, the gauge would be installed utilizing the two connector fittings at the unused outlet port See below for additional information on the gauge kits.

Option Codes

Use the following option codes to design any of the six models to meet your particular application. The standard type of bowl with the SWK 2000/5, /5/50, /10, & /18 is a clear bowl. The standard type of bowl with the SWK 2000/40 and /130 is a metal bowl.

Clear Bowl Standard

D = Clear Bowl with Heat Shield

M= Metal Bowl (U.S.C.G. and RINA Approved)

G = Vacuum Gauge (see below for optional Gauge Kits)

K = Contacts for water level indication

D= Clear bowl, w/metal heat deflector and contacts

U = Duplex Assembly

The shopping cart includes many popular configurations and provides the option of adding the Gauge Kit(s) to all configurations, but if you are looking for a configuration that is not included in the shopping cart, please call us and we will quote a custom configuration if it is available for the model you are looking for.

Optional Add-On Gauge Kit(s)

Each Gauge Kit has one Pressure/Vacuum Gauge (formerly part #30652-S) and two fittings that allow for mounting the gauge in one of the unused outlet ports of the filter assembly (see Stage 5 of “How the SEPAR 2000 Operates” section above). This allows for easier removal and handling of the lid of the filter when changing the filter element and lid gasket.

Gauge Kits for Separ Filters — Choose Gauge Kit Option on the product page for the Separ Single or Duplex Assembly you are purchasing in the Shopping Cart to include a gauge for the Separ Filter of your choice or to view pricing:

- SWK-2000/5 & SWK-2000/5/50 – Single Filter: Part # 14-0001 (Duplex Filter requires 2 Gauge Kits)

- SWK-2000/10 – Single Filter: Part #14-0002 (Duplex Filter requires 2 Gauge Kits)

- SWK-2000/18 – Single Filter: Part # 14-0003 (Duplex Filter requires 2 Gauge Kits)

- SWK-2000/40 – Single Filter: Part # 14-0004 (Duplex Filter requires 2 Gauge Kits)

If you wish to add a gauge to a Separ Filter you already have, you may order the Gauge Kit you need separately (or two for a Duplex Filter Assembly).

Specification Footnotes

Footnote 1: The Separ 2000/5/50 is 1.38 inch taller than the 2000/5 in the body to accommodate a slightly taller filer element. Flow rate and most other characteristics of the two models are otherwise the same.

Footnote 2: Separ filters with other Option Combinations than included on our shopping cart list to the right are available but must be special ordered. Please contact us for price and availability.

Footnote 3: The “G” option of a vacuum gauge to determine when filters need back-flushed or replaced may be added to any configuration. Adding to any single filter purchase adds one pressure/vacuum gauge (see Gauge Kits above), and adding the “G” option to any Duplex Assembly filter purchase adds two gauges (two Gauge Kits), one to each filter. See shopping cart for price.

BACKFLUSHING

Backflushing is required when dirt and water block the filter element. The following signs will indicate this procedure is necessary:

- Loss of engine power

- Black smoke may exhaust from the engine

- Vacuum gauge will indicate a high restriction reading on the element of the filter.

BACKFLUSHING PROCEDURES

- Stop the engine or switch over to the spare filter on the switchable units

- Open the bleed screw

- This introduces atmospheric pressure into the filter

- The dirt particles and larger droplets of water will release from the bottom of the filter element

- Gravity will assist the dirt particles as they slowly fall to the bottom of the bowl

- Open the drain valve (PUSH IN AND TURN)

- The clean fuel above the filter will backflush through the filter element. This will release the smaller dirt and water particles.

- Drain the fuel until the dirt and water are removed from the filter and the bowl. Close the drain valve.

- Close the bleed screw (DO NOT OVER TIGHTEN)

- You may now start your engine or switch back to the clean filter. If the engine still lacks power, try backflushing the filter again. If restriction is still too high, change the filter element.

Fittings for Separ Filters

Separ filters are threaded as follows:

• Separ SWK 2000/5 and 5/50– Inlet and Outlet 12 mm Pipe Connection – 3/4″ 16 Straight o-ring SAE (Duplex Assemblies shipped with optional #8 Male JIC Flare (37°) adapter)

• Separ SWK 2000/10 — 7/8″ 14 Straight o-ring SAE (Duplex Assemblies shipped with #8 Male JIC Flare (37°) adapter)

• Separ SWK 2000/18 — 1 1/16″ 12 Straight o-ring SAE (Duplex Assemblies shipped with #12 Male JIC Flare (37°) adapter)

• Separ SWK 2000/40 — 1 15/16″ 12 Straight o-ring SAE (Duplex Assemblies shipped with #20 Male JIC Flare (37°) adapter)

• Separ SWK 2000/130 — 2″ NPT Pipe (Duplex Assemblies 2″ shipped with FNPT adapter)

Additional Information:

Separ Filter Shopping Cart

- Sorry, this product cannot be purchased.

Separ Replacement

Filter Elements &

Gaskets

-

Separ Filter SWK 2000-5-50 (7)

Separ Filter Elements for the SWK 2000/5-50 Available for the Separ SWK 2000/5-50 Fuel Filter/Water Separator in: • 10 Micron • 30 Micron • 60 Micron Screen Stainless Steel Don’t forget to replace your Lid Gasket and Bowl Gasket regularly when changing filters. If you carry spare filters for use when you are underway or operational, keep a spare lid… -

Separ Filter SWK 2000-5 (7)

Separ Filter Elements for the Separ SWK 2000/5 Available for the Separ SWK 2000/5 Fuel Filter/Water Separator in: • 10 Micron • 30 Micron • 60 Micron Screen Stainless Steel Don’t forget to replace your Lid Gasket and Bowl Gasket regularly when changing filters. If you carry spare filters for use when you are underway or operational, keep a… -

Separ Filter SWK 2000-40 (7)

Separ Filter Elements for the Separ SWK 2000/40 Available for the Separ SWK 2000/40 Fuel Filter/Water Separator in: • 10 Micron • 30 Micron • 60 Micron Screen Stainless Steel Don’t forget to replace your Lid Gasket and Bowl Gasket regularly when changing filters. If you carry spare filters for use when you are underway or operational, keep a… -

Separ Filter SWK 2000-18-130 (9)

Separ Filter Elements for Separ SWK 2000/18-130 Available for the Separ SWK 2000/18-130 Fuel Filter/Water Separator in: • 10 Micron • 30 Micron • 60 Micron Screen Stainless Steel Don’t forget to replace your Lid Gasket and Bowl Gasket regularly when changing filters. If you carry spare filters for use when you are underway or operational, keep a spare… -

Separ Filter SWK 2000-10 (7)

Separ Filter SWK 2000/10 Elements are available for the Separ SWK 2000/10 Fuel Filter/Water Separator in: • 10 Micron • 30 Micron • 60 Micron Screen Stainless Steel Don’t forget to replace your Lid Gasket and Bowl Gasket regularly when changing filters. If you carry spare filters for use when you are underway or operational, keep a spare lid…