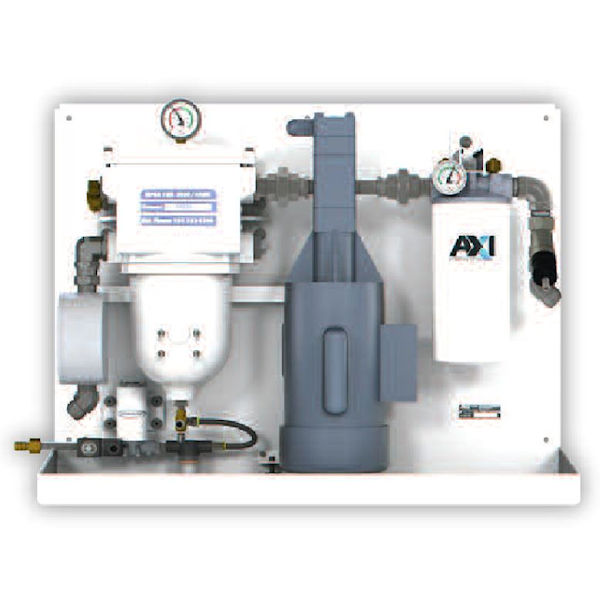

FPS Series Compact Fuel

Polishing Systems

Specifications for Each FPS Compact Fuel Polishing System

FPS DX-S Compact Fuel Polishing System

Flow Rate

1.3 GPM / 80 GPH (5 LPM / 302.8 LPH)

Serviceable Tank Size

200 to 900 gallons (750 to 3,400 ltr)

Motor

1/3 HP Continuous-Duty Motor with Coupled Gear Pump

Pump

Gear Pump

Power

12V DC 10A or 24V DC 5A

Max. Fluid Viscosity

5 cSt

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil,

water, antifreeze

Plumbing

Stainless Steel

Port Size

1/2″ NPT male port with Hose Barb – In & Out

Primary Filter

50 mesh/297 Micron Cleanable Screen

Secondary Filtration

Spin-On Filter

Pressure Gauge

Secondary Filter to Alert for Filter Changes

Plumbing

Stainless Steel

Construction

Powder Coated Aluminum Back Plate (Enclosure Optional)

Suction Capability (Primed)

10 feet (304.8 cm) Total Dynamic Head

Operating Temperature

41 – 104 deg. F

(5 – 40 deg. C)

Alarm Features

Pump Shut-Down,

High Vacuum,

High Pressure,

&Leak Detection

Weight

20 lbs +/- (9.1 kg)

Dimensions

(H x W x D)

15″ x 18.5″ x 75″(38 x 47 x 19 cm)

Optional

Enclosure

Powder Coat,

20″ x 20″ x 12″

Not for use with fluids that have a flash point below 100 deg. F.

FPS Compact – Compact Fuel Polishing System

Flow Rate

1.3 GPM / 80 GPH (4.9 LPM / 302.8 LPH)

Serviceable Tank Size

200 to 900 gallons (750 to 3,400 ltr)

Motor

1/3 HP Continuous-Duty Motor with Coupled Gear Pump

Pump

Gear Pump

Power

12V DC 10A or 24V DC 5A

Max. Fluid Viscosity

5 cSt

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil,

water, antifreeze

Plumbing

Stainless Steel

Port Size

1/2″ NPT male port Hose Barb – In & Out

Primary Filter Elements

Secondary Filtration

N/A

Construction

Powder Coated Aluminum Back Plate (Enclosure Optional)

Suction Capability (Primed)

10 feet (304.8 cm) Total Dynamic Head

Operating Temperature

41 – 104 deg. F

(5 – 40 deg C)

Alarm Features

Pump Shut-Down,

High Vacuum,

High Pressure,

& Leak Detection

Weight

20 lbs +/- (9.7 kg)

Dimensions

(H x W x D)

14″ x 10″ x 8″ (36 x 25 x 20 cm)

Not for use with fluids that have a flash point below 100 deg. F.

FPS FX Compact Fuel Polishing System

Flow Rate

2.5 GPM / 150 GPH (9.5 LPM / 567.8 LPH)

Serviceable Tank Size

500 to 2,000 gallons (1,900 to 7,600 ltr)

Motor

1/3 HP Single Phase, Continuous-Duty, Thermally Protected, TEFC

Pump

Helical Spur Gear Pump

Power

12V DC 10A or 24V DC 5A

Max. Fluid Viscosity

5 cST

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil,

water, antifreeze

Plumbing

Stainless Steel

Port Size

1/2″ Equivalent – JIC 37 deg. Flare – Inlet & Outlet

Primary Filter Elements

Secondary Filtration

N/A

Construction

Powder Coated Aluminum Back Plate (Enclosure Optional)

Suction Capability (Primed)

10 feet (304.8 cm) Total Dynamic Head

Operating Temperature

41 – 104 deg. F

(5 – 40 deg C)

Alarm Features

Pump Shut-Down,

High Vacuum,

High Pressure,

&Leak Detection

Weight

32 lbs +/- (14.5 kg)

Dimensions

(H x W x D)

20″ x 17″ x 7″ (51 x 43 x 18 cm)

Not for use with fluids that have a flash point below 100 deg. F.

FPS SX-F Compact Fuel Polishing System

Flow Rate

2.5 GPM / 150 GPH (9.5 LPM / 567.8 LPH)

Serviceable Tank Size

500 to 2,000 gallons (1,900 to 7,600 ltr)

Motor

1/3 HP single phase, continuous duty, thermally protected, TEFC

Pump

Gear Pump

Power

110V / 60Hz 15A or 230V / 50Hz 15A

Max. Fluid Viscosity

5 cST

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil,

water, antifreeze

Plumbing

Stainless Steel

Port Size

3/4″ Equivalent – JIC 37 deg. Flare Inlet / 1/2″ Equivalent – JIC 37 deg. Flare Outlet

Filtration Controller

SFC-70 Programmable, Fully Automated Filtration Controller, with option to upgrade to the TSC-70 Programmable Filtration Controller with Additional Functionality

Primary Filter Elements

Secondary Filtration

Spin-On Filter

Construction

Powder Coated Aluminum Back Plate

Suction Capability (Primed)

10 feet (304.8 cm) Total Dynamic Head

Operating Temperature

41 – 104 deg. F

(5 – 40 deg C)

Alarm Features

Pump Shut-Down,

High Vacuum,

High Pressure,

&Leak Detection

Weight

57 lbs +/- (25.9 kg)

Dimensions

(H x W x D)

23″ x 26″ x 9″ (58 x 69 x 23 cm)

Not for use with fluids that have a flash point below 100 deg. F.

FPS MX-F Compact Fuel Polishing System

Flow Rate

4 GPM / 260 GPH (15.1 LPM / 906 LPH)

Serviceable Tank Size

3,000 to 6,000 gallons (11,400 to 22,700 ltr)

Motor

1/3 HP single phase, continuous duty, thermally protected, TEFC

Pump

Helical Spur Gear Pump

Power

110V / 60Hz 15A or 230V / 50Hz 15A

Max. Fluid Viscosity

5 cST

Fluids

Diesel Fuel, Hydraulic, Engine & lube oil,

water, antifreeze

Plumbing

Black Iron

Port Size

3/4″ Equivalent – JIC 37 deg. Flare – Inlet / Outlet

Primary Filter Elements

Secondary Filtration

Spin-On Filter

Construction

Powder Coated Aluminum Back Plate

Suction Capability (Primed)

15 feet vertical lift or 100 ft. horizontal run (lines > 1″

Operating Temperature

41 – 104 deg. F

(5 – 40 deg C)

Alarm Features

Pump Shut-Down,

High Vacuum,

High Pressure,

&Leak Detection

Weight

40 lbs +/- (31.8 kg)

Dimensions

(H x W x D)

23″ x 26″ x 9″ (58 x 69 x 23 cm)

Not for use with fluids that have a flash point below 100 deg. F.

FPS LX-F Compact Fuel Polishing System

Not for use with fluids that have a flash point below 100 deg. F.

Frequently Asked

Questions

The fuel flow first enters the Fuel Conditioner immediately upon exiting the fuel pump. Operating on the principal of induction on the process of combining kinetic and magnetic energy to influence the behavior of electrons, the Fuel Conditioner provides a powerful magnetic field and the flow of fuel provides the kinetic energy.

As fuel deteriorates, clusters of fuel components break down and residue begins to accumulate, resulting in dark, hazy fuel with poor combustibility. This residue is composed primarily of asphalt components of the crude oil from which diesel fuel is refined that have fallen out of solution. The fuel becomes dark as the asphaltenes agglomerate and gain weight. The increase in size and mass of the fuel breakdown products lead to clogged filters and the build up of tank sludge.

As fuel deteriorates, clusters of fuel components break down and residue begins to accumulate, resulting in dark, hazy fuel with poor combustibility. This residue is composed primarily of asphalt components of the crude oil from which diesel fuel is refined that have fallen out of solution. The fuel becomes dark as the asphaltenes agglomerate and gain weight. The increase in size and mass of the fuel breakdown products lead to clogged filters and the build up of tank sludge.

Accumulation of water in the fuel tank provides habitat for bacterial and microbes brought into the tank through the breather vent or with fuel. As this microbial growth grows and reproduces, a bio-film accumulates and attaches to the tank walls and baffles of the fuel tank and may be seen floating in the fuel (and sometimes referred to mistakenly as “algae”).

This accumulation of bio-mass and fuel breakdown clogs filters, adversely impacts combustion efficiency, produces dark smoke from the exhaust, form acids that degrade injectors and fuel pumps, and adversely impacts performance. Eventually fouled diesel fuel will clog fuel lines and ruin your equipment.

The Fuel Conditioner dissolves the clusters, stabilizes the fuel, and eliminates tank sludge. The results are Clear & Bright Fuel, improved filterability, optimal combustion and clean fuel systems. It also adversely impacts the reproduction process of the microbes and prevents further growth (see the article “Why Bacteria Hate Magnets“, allowing continuing use of the fuel to eliminate the microbes. The process of how the Fuel Conditioner makes clear, bright and more combustible fuel as well as restoring degraded fuel and eliminating the effects of microbial contamination is compelling. As the Fuel Conditioner does not filter the fuel, but treats it as it passes through the unit, there is seldom any reason to suspect that a restriction is in the Fuel Conditioner. But you can remove the face plate, remove the magnet and wipe it off with a shop rag and replace the magnet and face plate. A spare parts kit for the Fuel Conditioner includes a new face panel O-Ring and replacement screws to fasten the face plate.

The Fuel Conditioner dissolves the clusters, stabilizes the fuel, and eliminates tank sludge. The results are Clear & Bright Fuel, improved filterability, optimal combustion and clean fuel systems. It also adversely impacts the reproduction process of the microbes and prevents further growth (see the article “Why Bacteria Hate Magnets“, allowing continuing use of the fuel to eliminate the microbes. The process of how the Fuel Conditioner makes clear, bright and more combustible fuel as well as restoring degraded fuel and eliminating the effects of microbial contamination is compelling. As the Fuel Conditioner does not filter the fuel, but treats it as it passes through the unit, there is seldom any reason to suspect that a restriction is in the Fuel Conditioner. But you can remove the face plate, remove the magnet and wipe it off with a shop rag and replace the magnet and face plate. A spare parts kit for the Fuel Conditioner includes a new face panel O-Ring and replacement screws to fasten the face plate.

If a tank has a straight-line access to the bottom of the fuel tank from the fuel fill hole or through another inspection port, a length of PVC, PEX or similar material pipe, 1/2 inch in diameter, can be used like a soda straw to sample what is in the bottom of a tank. Cut the pipe to length to allow insertion of the pipe to the bottom of the tank while allowing your thumb to cover the exposed end of the pipe. With your thumb over the end, insert the pipe to the bottom of the tank, remove your thumb so what is at the very bottom will rush into the tube to the level of fuel in the tank. Again place your thumb over the end of the pipe and extract the pipe, maintaining the liquid and other materials inside the tube. Place an empty clear plastic 2 liter soft drink bottle upright in the bottom of a empty 5-gallon bucket. Direct the end of the tube into the drink bottle (any spilled liquid will be caught inside the five gallon bucket). Perform this action several times. Allow the contents of the bottle to settle (ideally overnight) and inspect the materials in the bottom of the drink bottle. Any debris or water should be apparent.

If your tank is larger and using a tube to recover fuel, water or other debris from the bottom of the tank is not possible, you can use a Tank Sample (TS) Fluid Sampler. You can take 4 oz., 8 oz, or 16 oz. samples using the AXI Tank Sampler.

You can also use the FS 100 Hand Pump to pull fuel through a length of tubing and into a Sample Bottle. Instructions for using the Hand Pump is on the Fuel Sampling Devices web page.

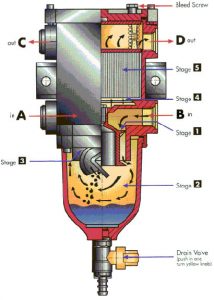

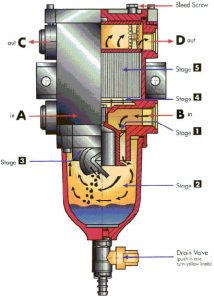

The following is the five stage fuel system of the typical Separ SWK-2000 Fuel Filter/Water Separator:

- Stage 1: From the inlet port, fuel flows through the interior vane system which imparts a circular motion to the fuel.

- Stage 2: Still in circular motion fuel reaches the bowl section where, due to this centrifugal motion water droplets and heavier particles are forced to the wall of the bowl eventually settling in the bottom of the bowl.

- Stage 3: In this stage the fuel has to pass the vane system positioned on the “outside” of the central housing. Due to differing length of the vanes and the twofold rapid change of fuel flow direction, smaller water droplets and finer particles will settle on the vanes. These settlements will agglomerate and when heavy enough fall to the bottom of the bowl. Already at this point the major portion of any contaminates in the fuel have been separated.

- Stage 4: Just below the filter element the flow area of the filter is increased significantly thus reducing the fuel flow rate. This calming effect allows even smaller water droplets and particulate to fall out settling on the inner surfaces of the housing forming larger droplets which eventually fall into the bottom of the bowl by gravity. Due to the before described pre-separation process the major portion of water and particulate present in the fuel will be in the bowl or on the inner surfaces of the filter thus greatly extending the filter element life.

- Stage 5: The final filtration of the remaining water and particulates still contained in the fuel will be effected by a replaceable filter element. These filter elements are produced from a special filter media and are available in different pore sizes. The clean fuel leaves the filter via one of the two outlet ports.

A Vacuum Gauge is provided on the top lid of the Separ Fuel Filter/Water Separator to allow for visual monitoring of Vacuum. When the Vacuum reading increases, indicating that the replaceable filter element has reached its capacity for holding particulate material, you know the filter needs changing. No more guessing or changing the filter too soon.

It is not unusual that a Fuel Polishing and Tank Cleaning System is installed at a level above the fuel that is to be maintained, especially in underground tanks or base (or “belly”) tanks of generators. How do you maintain the prime on the pump in such an installation?

Foot Valves are handy little devices that can be installed at the end of a pipe line in a suction lift application. They function as a check valve to maintain the prime and also have a strainer affixed to the open end. The check valve is spring assisted. When the pump is turned on, the suction opens the valve and the fluid flows. When the pump stops, the valve responds again by closing. This stops fluid from draining out of the pump column and causing the pump to lose prime every time it turns off.

Foot Valves are handy little devices that can be installed at the end of a pipe line in a suction lift application. They function as a check valve to maintain the prime and also have a strainer affixed to the open end. The check valve is spring assisted. When the pump is turned on, the suction opens the valve and the fluid flows. When the pump stops, the valve responds again by closing. This stops fluid from draining out of the pump column and causing the pump to lose prime every time it turns off.

The strainer also keeps debris from becoming lodged in the foot valve. This would result in the valve being stuck in the open position, and all the fluid draining from the pump column. That nullifies the point of the foot valve! Some foot valves offer tight mesh, others offer a wider grid strainer.

Any installation of a Fuel Maintenance System dedicated to the cleaning and conditioning of fuel in one or multiple tanks would benefit from the inclusion of a foot valve. The efficiency of a system that is programmed to operate on a periodic basis would suffer if an operator must prime the pump each time a tank is due for maintenance.

The Multi-Port Flowpath Actuated Valve System is available to operate in unison with several of the FPS Fuel Polishing Systems. Each MP-VS Valve Set includes two (2) Solenoid Valves (one for the suction and one for the discharge line) and one Foot Vale to be installed on the end of the suction pipe. One valve set is typically installed in each partitioned section of the base tank.

Clogged Filters, Dirty Tanks?

FPS Series Systems Clean Fuel

Frequent Filter changes and incurring the expense and inconvenience of cleaning fuel tanks have become acceptable periodic maintenance instead of a warning signal for engine failure. Filter elements should last a thousand hours or more, and your engine’s diesel fuel injectors some 15,000 hours. However, since diesel fuel is inherently unstable, solids begin to form and the accumulating tank sludge will eventually clog your filters, cause engines to smoke, and eventually ruin your engine’s diesel injectors.

Fuels and oils are susceptible to natural deterioration, like any other organic fluid. Oxidation, chemical incompatibility, water and microbial infestation all contribute to the process of polymerization and stratification of diesel fuel and other hydrocarbons. This results in poor Fuel Quality, and the formation of tank sludge, bio film and acids. These by-products of the process of fuel breakdown cause clogged filters, corroded injectors, pumps and tanks, incomplete combustion (evident from black smoke, caused by un-burned fuel, from exhaust), carbon build-up on engine components, and loss of power. As these problems build on each other, these individual symptoms of bad fuel ultimately lead to complete engine failure.

Filters, separators, and centrifuges remove particles and free water from fuel. Biocides, commonly recommended by many mechanics to cure the ills of “algae” in fuel tanks, are really less than effective in the long term control of microbial activity. Neither, however, eliminates fuel instability or sludge buildup in tanks. Biocide treatments aggravate filtration problems by turning bio-sludge into solids. Removal of fuel tanks for cleaning with high pressure washers or steam (a favorite recommendation of equipment dealers) is expensive, takes equipment out-of-service, necessitates the removal and disposal of fuel from tanks, and is likewise ineffective and does not provide a long term solution.

A study by the University of Idaho determined that there could be as much as a 26% degradation in diesel fuel after just 28 days of storage. See the article “Fuel Polishing: How It Really Works” on this website.

Diesel Fuel is Inherently Unstable

Diesel engines continuously return fuel not used for combustion back to the tank. The repeated exposure to the heat and pressure of the injection system accelerates this breakdown of fuel quality. Fuel quality and fuel chemistry is affected by transportation, storage tank conditions as well as time, and factors such as oxidation, water in the fuel, microbial contamination (contributing to acid formation), and incompatibility of fuel additive packages with after-market additives, etc. This toxic combination negatively impacts: (i) the filterability of the fuel through filters that become clogged; and (ii) causes a dramatic increase in the size of the fuel droplets emitted from the fuel injector into the combustion chamber. The degraded condition of the fuel, when combined with the injector degradation that occurs over time from the use of the degraded fuel, result in fuel not being completely burned in the combustion chamber and formation of carbon deposits on internal engine components, all evidenced by a noticeable increase in smoke from the exhaust, loss of power, and an increase in fuel consumption. (See “Diesel Fuel & Injector Failures” for additional information)

FPS Series Fuel Polishing Systems

The FPS Compact Systems are wall-attached systems for use in applications where space is at a premium (i.e.: marine engine areas or generator cabinets) or where the Fuel Polishing System will not be out-of-doors and otherwise protected from weather and the elements.

- Programmable Runtime Scheduling

- Fully Automated

- Digital Text Readout

- Primary Filter High Water Alert/Shutdown

- High Pressure/Vacuum Shutdown

- Leak Detection Shut Down

- Smart System Alerts/Alarms

12 Volt or 24 Volt Powered Systems (see detailed specifications at left of page):

- FPS DX-S – 80 GPH – Features economic Fuel Polishing that includes Programmable Digital Timer & Alert Functionality, primary filter screen, and secondary filtration spin-on filter

- FPS-Compact – 80 GPH – Features compact components for extremely small space usage, such as generator cabinets where space is especially cramped – features remote location of the Programmable Digital Timer & Alert System Monitor

- FPS-FX – 150 GPH Rating – features high volume Fuel Polishing in a compact package

A/C Powered System (see detailed specifications at left of page):

- FPS SX-F – 150 GPH – Features remote mounted Automated Intelligent Controller and remote mounted Controller

- FPS MX-F – 260 GPH –

- FPS LX-F – 600 GPH

Fuel Conditioner

LG-X Series

Fuel Conditioner

Critical to the Fuel Polishing process is the Fuel Conditioner. Without this component, all you accomplish is the filtering of your fuel. The Real Story of Bad Diesel Fuel is that there are two main causes of Fuel Problems:

- Micro-organisms, bacteria and enzyme activity, fungus, yeast and mold get into your fuel that cause diesel fuel degradation and the formation of waste products that can be visible floating around in your fuel tank (commonly, but erroneously, referred to as “algae”).

- Diesel Fuel begins to degrade with age as soon as it leaves the refinery. The asphaltene component of diesel fuel (the heaviest asphalt portion of the crude oil) that is in suspension in the fuel when it leaves the refinery, but begins agglomerating and leads to larger and larger clusters and solids, which are very difficult to completely combust (causing exhaust smoke). As these solids grow, they will not pass through the filter element and result in filter plugging after a very short period of time.

The Fuel Conditioner not only prevents both problems, it will prevent the microbial contamination from growing, and will reverse the breakdown of the heavy constituents of diesel fuel that cause the fuel to become dark or black, restoring the fuel to the clear, bright condition it had when it left the refinery and return the fuel to the state of optimal quality, hence the term “Fuel Polishing”. For a complete understanding of the importance of the Fuel Conditioner in your fuel maintenance program, read the “Diesel Fuel Polishing” article on this website.

Primary Filter Fuel / Water Separator

SEPAR Filter

Cut-Away

The Primary Separ Fuel / Water Separator will remove water from the fuel as your FPS Compact Series Fuel Polishing System operates. The water accumulates in the bowl of the filter unit. The water should be removed periodically when the capacity of the bowl is reached (see details on the Separ Fuel / Water Separator web page).

Secondary Filtration

Except for the FPS Compact (inside generator cabinet model) and FPS FX Fuel Polishing Systems (12 Volt powered systems), all other FPS Compact Series Fuel Polishing Systems are equipped with a secondary spin on filter. These filters are typically rated at three to ten microns and may be elements that are treated to retain water as the fuel passes through the cartridge, commonly referred to as a Water Block Filter. The filter head, which the filter cartridge is fastened to, is equipped with a pressure gauge that will display the “back pressure” indicating that a filter is approaching maximum capacity.

Programmable Digital System Monitor

Three of the FPS Series Compact Fuel Polishing Systems (those configured for DC power) are Standard with the Programmable Digital System Monitor. Use this link to review the operating features of this System Monitor.

- FPS DX-S — 80 GPH

- FPS Compact — 150 GPH

- FPS FX — 150 GPH

SFC-70 Automated System Controller

Three of the FPS Series Compact Fuel Polishing Systems (those configured with AC power) are available with the SFC-70 Programmable Automated System Controller. Use this link to review the operating features of this System Controller.

- FPS SX-F System — 2.5 GPM

- FPS MX-F System — 4 GPM

- FPX LX-F System — 8 GPM

The SFC-70 Controller features programmable runtime scheduling, system alerts and alarms, including automatic pump stop, Modbus TCP/IP & Summary Dry Contacts.

An upgrade to the optional TSC70 Controller provides the convenience of LCD/Touchscreen controls.

Powder Coated Enclosure

The FPS DX-S 80 GPH Compact Fuel Polishing System (available in either 12 V or 24 V) has the unique feature of being available with the option of a Powder Coated Steel Enclosure. The enclosure measures 20 in. x 20 in. x 12 in.

If you are considering the FPS-SX-F, FPS MX-F, or the FPX LX-F, and your requirements include an enclosed cabinet, consider the STS 6000 SX-F, STS 6003, STS 6004 or STS 6010 Systems. These Systems have the equivalent functionality with an enclosed cabinet. Systems placed into service in regions that experience very cold conditions benefit greatly from enclosed cabinets and the addition of an optional cabinet heater to protect the Systems components from damage.

AFC Series Fuel & Tank Cleaning Additives

Critical to maintaining fuel in its optimal quality and the management of fuel tanks and engine injector components is the use of an additive treatment program.

The AFC Fuel Catalyst family of additives are formulated for use in diesel, gasoline, bio-fuels, kerosene and Heavy Fuel Oil (also known as heavy fuel oil or residential fuel oil).

AFC Fuel Catalyst is not like other additives readily available at truck stops, auto and truck parts retailers, marine supply stores, or sold by numerous on-line suppliers. AFC is formulated and blended for the focused dual-purpose of:

AFC Family of Diesel Fuel Additives

First – working hand-in-hand with the LG-X Series Fuel Conditioners, and the FPS Series of Compact Fuel Polishing and Tank Cleaning Systems cleaning fuel tanks in preparation for periodic circulation and treatment of the fuel; and

Second – as a continuing part of a Fuel Management Plan to maintain the cleanliness of storage tanks and fuel systems and assuring that your fuel maintains Optimal Fuel Quality, that we define as fuel that is like it was when it left the refinery, for as long as you depend on the fuel to efficiently operate your equipment.

Optional Features

- Manual Additive Injection – Manually draw additive into the Fuel Polisher with a dedicated supply port and ball valve. Also see the Tank Cleaning Additives below

- Auto Water Drain (AWD) – Automatically drain water separator of collected water for decreased frequency of maintenance. Includes water collection tank and Controller control when tank reaches capacity.

- Flow Transmitter – Replace standard flow switch for detailed monitoring of flow rate in the system

- Multi-Tank Polishing/Transfer – Polish and transfer fuel between multiple fuel storage tanks (up to 2-tanks, 4-tanks with TSC-70 Controller upgrade)

- Multi-Port Flow Path – Add multiple supply and return valves for better tank cleaning coverage (Requires upgrade to TSC-70 Controller)

- Fuel Heater – Warm up circulated fuel to resist gelling in freezing temperatures

Upgrade to the TSC-70 Advanced Automated System Controller may be required for certain option combinations.

Additional Optional Features

- Power Converter – for 12 / 24 Volt systems to operate from 110-Volt to 230-Volt power.

- Alarm Strobe: provides flashing light signal that System shut down and maintenance service is required.

- Audible Alarm: provides audible signal that System shut down and maintenance service is required

- Digital Flow Meters: provides digital readout of volume of fuel treated.

- Replacement Filters: for your FPS Series Fuel Polishing System. Also see the “Additional Information” section below for Replacement Fuel Filters for the various FPS Series Systems.

- Extended System Warranty – Maximum 4 years (contact us for details).

An Ounce of Prevention is Worth a Pound of Cure

The following are products that are available on the diesel-fuels.com website that will help you in preventing debris, microbes and moisture from entering your fuel tank, and removing them early before they may cause problems. Also, other products to help with fuel and fuel tank maintenance:

- AFC Series Fuel Additives for fuel conditioning, stabilization, tank cleaning, and combustion catalyst. Also see the “Additional Information” section below for information on Tank Cleaning Additives.

- Breather Vent Filters with desiccant material that will stop debris and moisture from entering your fuel tank through the vent breather.

- WE-12 Water Eliminators capture and hold water from condensation that may accumulate in your fuel tank.

- Diesel Recovery quickly dissolves gelled fuel caused by cold temperatures and thaws frozen fuel lines and filters.

- Access Plates for creating a removable access port in fuel tanks to accommodate inspections and tank maintenance.

- Fuel Sampling Devices ease the recovering of fuel for testing from your fuel storage tank. TS Series Samplers are dropped into the tank and capture a sample from different depths. A hand pump is also available for obtaining samples. Sample bottles are also available for use with both options.

- Fuel Testing Kits provide an early warnings of the presence of contamination in your fuel.

Additional Information

- Replacement Fuel Screen TK-070 — FPS DX-S

- Replacement Fuel Screen/Filters Goldenrod — FPS CX-F

- Separ Replacement Filters for the Separ SWK 2000/05 — FPS DX-S, FPS Compact,

- Separ Replacement Filters for the Separ SWK 2000/10 — FPS FX-F, & FPS SX-F

- Separ Replacement Filters for the Separ SWK 2000/18 — FPS MX-F

- Separ Replacement Filters for the Separ SWK 2000/40 — FPS LX-F

- Spin-On Replacement Filters for FPS-DX

- Spin-On Replacement Filters for the FPS SX-F, FPS MX-F, FPS-LX-F, & FPS CX-F

- AFC-705 — Formulated for pre-2007 model year diesel engines (includes surfactants)

- AFC-710 (Tier 4 compliant) — Formulated for post-2007 model year diesel engines (available in powder form for ease of handling and transport)

- AFC-805 — formulated for long term fuel storage, such as bulk fuel farms, winterized recreational and work boats, and smaller engines.